RESEARCH

The COI Program aims to establish an innovation platform

through industry-academia collaboration,

and to realize radical innovation that is difficult for industry and academia to accomplish on their own

OUTLINE

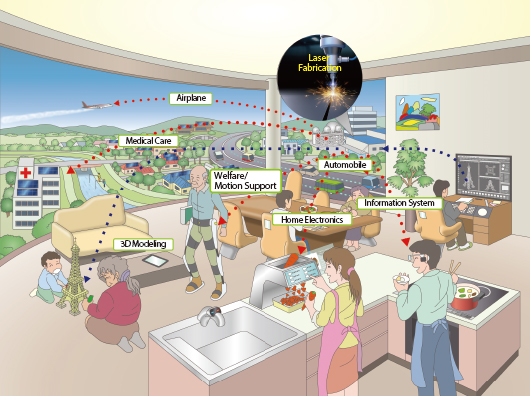

Our goal is to build a personalized, sustainable society by actively employing ideas arising from individuals and optimizing resource usage. With the photon as the basis of our organization and a solid scientific foundation that ensures the reliability of new technologies, we strive toward initiating a paradigm shift in manufacturing using coherent photon technologies. We create new technologies that are required to support the future vision of our society and industry; this will create a world wherein individual ideas and technologies will be actively exchanged among industries, academia, the government, and consumers.

Applications & Services

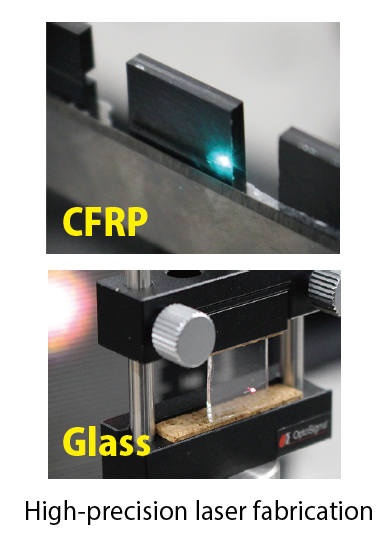

- High-precision laser fabrication techniques

- Non-thermal laser processing using short-wavelength, ultrashort-pulse, and high-intensity lasers will be applied to the high-precision freeform fabrication of carbon fiber reinforced plastics (CFRPs), which are currently key materials in the aircraft and automobile industries. In addition, the basic construction of cyber physical systems (CPSs) for laser processing, which is indispensable for the Internet of Things, will be established.

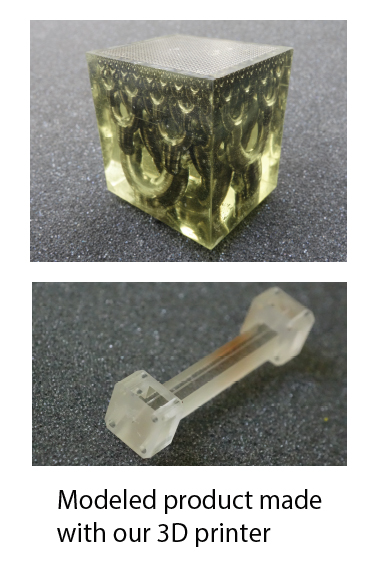

- 3D printer; RECILS

- RECILS is a new 3D printer that has realized both high-speed and high-resolution molding for the first time. RECILS can be applied in many fields including microfluidics, optical communication devices, honeycomb structure fabrication, and plastic part fabrication.

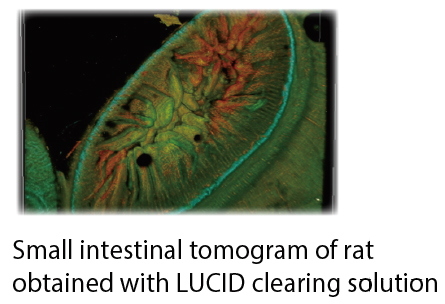

- Internal-organ observation system

- A unique microscope will be developed for observing lesions, such as tumors, inside organs using a tissue-clarification method called “LUCID,” which has been developed by us. Using this microscope technique, the cost and time spent on diagnostic techniques in pathology will be reduced.

Key R&D Themes

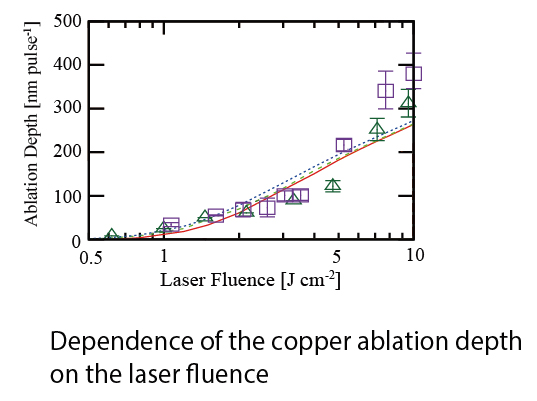

- Development of laser fabrication techniques for hard-to-process materials

- Non-thermal laser processing methods will be established for materials, such as CFRPs and tempered glass, which are difficult to process using a conventional laser.

[Junji Yumoto (Univ. of Tokyo), RIKEN, Mitsubishi Electric Co., Toray Industries, Inc.]

- Advanced laser molding and modifying techniques

- Using improved stereolithographic techniques, high-performance 3D printers (product prototypes) and their applications will be developed.

[Norikatsu Mio (Univ. of Tokyo), Toray Industries, Inc.]

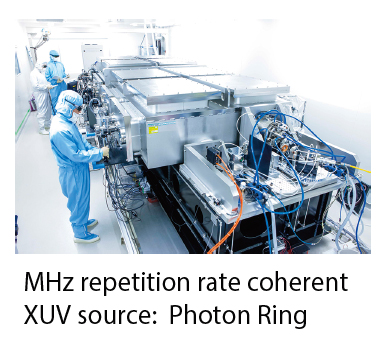

- Short-wavelength light sources and application technologies

- High-intensity laser sources, such as short-pulse sources in the ultraviolet (UV)–THz regions, will be developed as the core coherent technology and coherent light source for testing extreme UV lithography (EUV) optics.

[Katsumi Midorikawa (RIKEN), Univ. of Tokyo, Gigaphoton, Inc.]

- Exploration of individual needs

- Lightweight walking support systems without power supply will be developed using the abovementioned laser fabrication and 3D printing techniques. Additionally, internal organ observation systems that reliably detect interior lesions will be developed in conjunction with a clearing reagent.

[Hiroshi Onodera (Univ. of Tokyo)]

- Development of new non-equilibrium photo processes

- We will develop methods, such as sophisticated computer simulations based on first principles, mathematical modeling of multiple scales, and photoelectron spectroscopy experiments, to build a foundation for CPSs. Then, we will elucidate the theory of non-equilibrium light processes by analyzing light propagation, electronic excitation, and the resulting structural material changes.

[Shinji Tsuneyuki (Univ.of Tokyo)]