3D Printer RECILS

At ICCPT, we have been researching and developing RECILS, a

3D printer for high resolution, high speed, and palm-sized modeling.

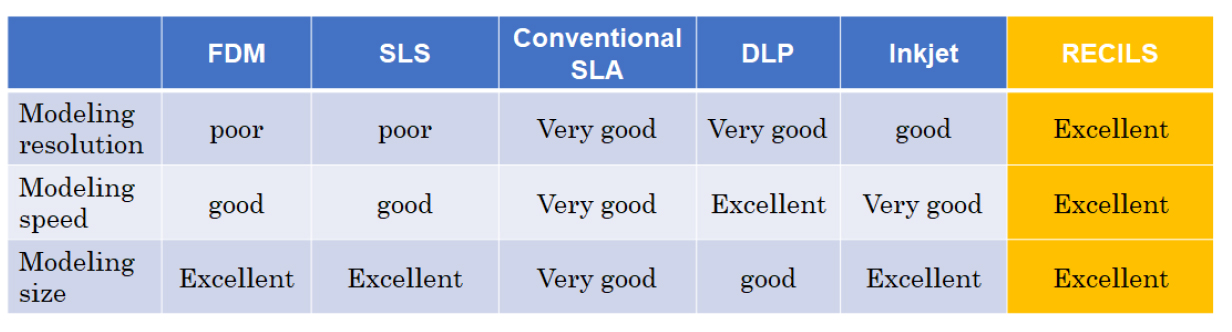

There are several types of 3D printers, as shown in Table 1. Fused Deposition Modeling (FDM)

is a simple method that discharges a heat-melted thermoplastic resin from a nozzle, forming

a modeling layer. However, FDM cannot produce the fine discharges required for

fine-structure modeling. Similarly, selective laser sintering (SLS) of sintering powder with

a laser is not suitable for forming fine structures. In conventional stereolithography

apparatus (SLA)-type 3D printers, a UV laser is scanned over a UV curable resin stored in a

glass tank. The laser is directed from below the tank, so the molding layer is formed on the

bottom of the tank. Fine structures can be formed by narrowing the laser beam. After each

layer is formed, the cured resin must be peeled from the bottom flat plate of the glass

tank. During this process, the formed fine structure is broken by the peeling resistance. If

the peeling is slowed to preserve the fine structure, the processing time is excessively

long. In the Digital Light Projector (DLP) method, the UV curable resin is selectively

exposed from under the tank by the light from a projector. DLP forms fine structures with

high accuracy at high speed, but its resolution decreases with increasing modeling size, and

the peeling problem remains. In addition to these methods, a material jetting method in

which the resin injected from the inkjet head is hardened with UV light is available. This

method is easy to handle, but the equipment and running costs are high. In some cases, the

surface is roughened by the support material, which can be a problem.

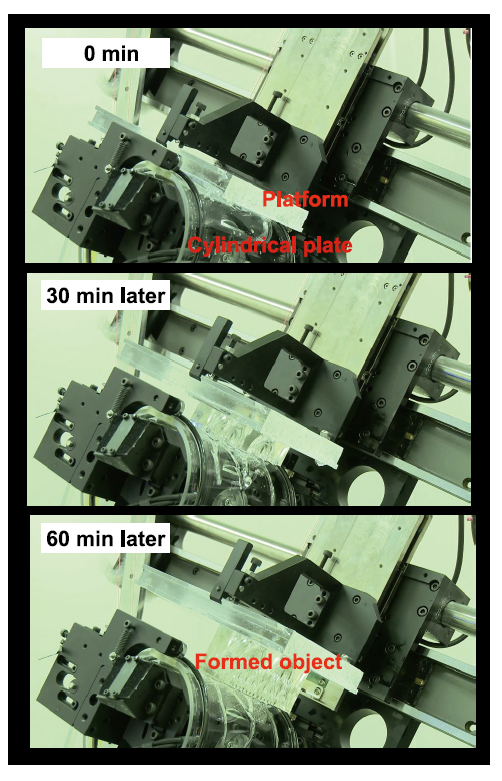

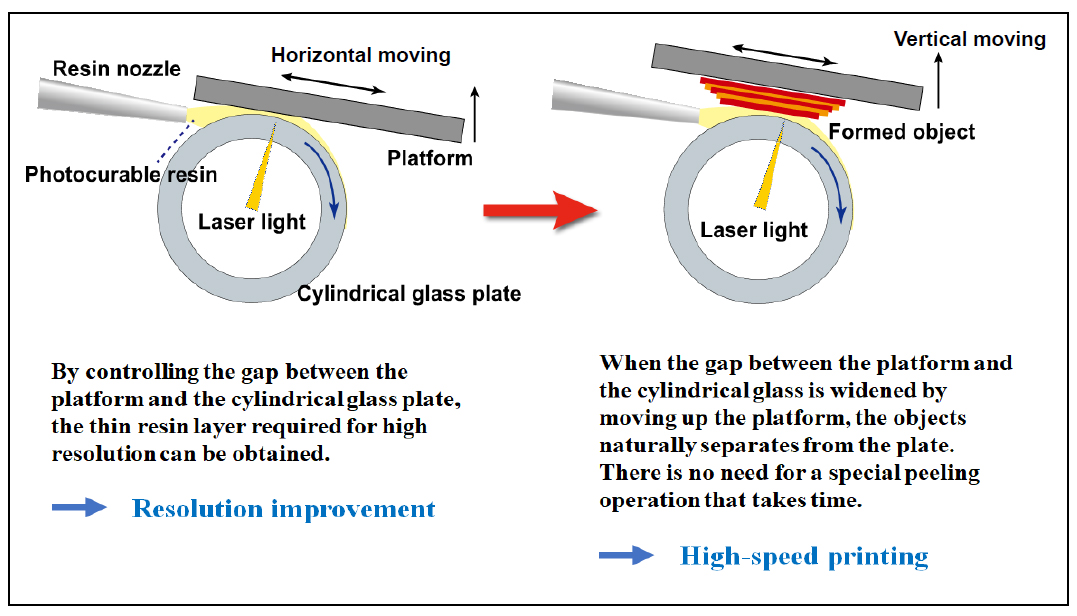

RECILS adopts the SLA method but replaces the conventional technology with a new technology,

as shown in Figs. 1 and 2. Most distinctly, the SLA is performed between the flat substrate

(platform) and a cylindrical glass plate (regulated liquid-level plate). First, the UV

curable resin is ejected from the nozzle onto the cylindrical glass plate, and the platform

is vertically moved toward the cylindrical glass plate until the set narrow gap (20–40 µm)

is reached. By this process, the UV curable resin is thinned to the correct thickness. The

thin UV curable resin is then raster-scanned with a UV laser focused to a spot size of

approximately 10 µm, while the substrate is moved in the horizontal direction, forming a

UV-cured planar image. By repeating this operation and stacking the images with vertical

movement, a three-dimensional object is formed.

The high-precision thinning performed by RECILS improves the resolution of the product. In

addition, the rotating cylindrical glass automatically separates itself and the formed

object layer without breaking the object’s fine structure. RECILS thus simultaneously

achieves high resolution and nonbreaking peeling. The robust peeling greatly reduces the

modeling time of RECILS. Furthermore, as the size and resolution of the model are

uncorrelated, the high resolution is maintained on enlarged models.

As an example, RECILS can form a three-dimensional structure with an approximate outer

dimension of 10 cm containing a fine groove with a width of 100 μm, which was previously

difficult to form. RECILS can manufacture wireless communication parts, such as waveguides

for high-frequency transmission, chemical and bio parts, such as microchips, and space

industry parts, such as end-burning-type hybrid rockets. Therefore, RECILS will assist

research and development activities in a wide range of industrial fields.

The trial production and modeling service with RECILS is provided by Photon Tech Innovations

Co., Ltd., a venture company from the University of Tokyo.

https://photontechinnovations.com/english

Fig. 1. Photographs of RECILS during the modeling process

Fig. 2. Modeling mechanism of RECILS

Table 1. Advantages and disadvantages of different modeling methods

FDM: Fused Deposition Modeling

SLS:Selective Laser Sintering

SLA: Stereolithography Apparatus

DLP: Digital Light Projector

Inkjet: Material Jetting